|

|

|

|

产品概述/Product overview |

|

规整填料塔的分离性能取决于内件,即填料、分布器、收集器等。同时也取决于许多参数,如气体负荷,液体负荷、物料性质、操作压力、填料湿润性能和液体分布不均匀等等。至今不能由填料的几何形状来精确计算塔的分离性能,需要通过填料塔的理论和不同条件下通过试验塔来测定准确数据。用户可根据资料以一级近似程度确定塔的尺寸和需要的填料高度。如果需要经济、合理的结构形式,我厂愿与用户密切合作。 |

|

The separation performance of structured packing columns depends on internal pieces, i.e. the packing, distributor and collector, etc. Besides it also depends on many parameters, including gas load, liquid load, material nature, operating pressure, humidity performance of the packing and uneven liquid distribution, etc. Up till now, it is impossible to calculate separation performance in an accurate manner of the columns based on physical dimension of the packing. Instead, accurate data shall be measured based on theory of packing columns and tests under different conditions. The user may decide size of column and required height of the packing of first order approximation based on the data. Our company is willing to perform close cooperation to provide structural form in an economic and reasonable manner if necessary. |

|

|

|

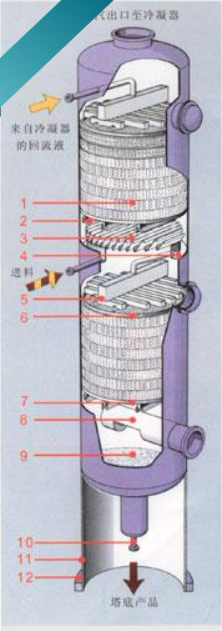

1、规整填料

2、支撑栅板

3、液体收集器

4、集液环

5、多级槽式液体分布器

6、填料压圈

7、支撑栅板

8、蒸汽入口管

9、塔底

10、至再沸腾循环管

11、裙座

12、底座环

1, the structured packing

2, support grid

3, liquid collector

4, liquid collection ring

5, multi-stage trough type liquid distributor

6, packing pressing ring

7, support grid

8, steam inlet pipe

9, column bottom

10, to re-boiling circulating pipe

11, skirt

12, base ring |

此结构适合于直径大于等于名800mm的填料塔

This structure is suitable for packing column

with diameter not less than 800 mm |

|

|

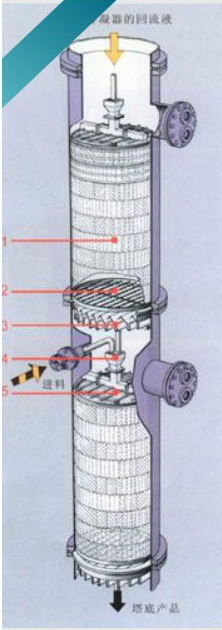

1、规整填料

2、支撑栅板

3、液体收集器

4、降压管

5、管式液体分布器

1, the structured packing

2, support grid

3, liquid collector

4, pressure reducing pipe

5, tubular liquid distributor |

此结构适合于直径小于800mm的填料塔

This structure is suitable for packing column

with diameter less than 800 mm |

|

|