- Crystallizer Series

- MVR Evaporators

- Complete System Engineering

- Scraper type film evaporator

- Distillation tower equipment

- Energy-Saving Sewage

- Waste Water Sewage

- Energy-Saving Waste Water

- Reaction & stirring equipment

- Heat-Exchange Condensing

- Drying and Dispersing Equipmen

- Tank Series

- Fermentation Equipment

- Concentration Evaporation Faci

- Extraction, Filtration, Precip

|

产品工作原理 Working principle of the product

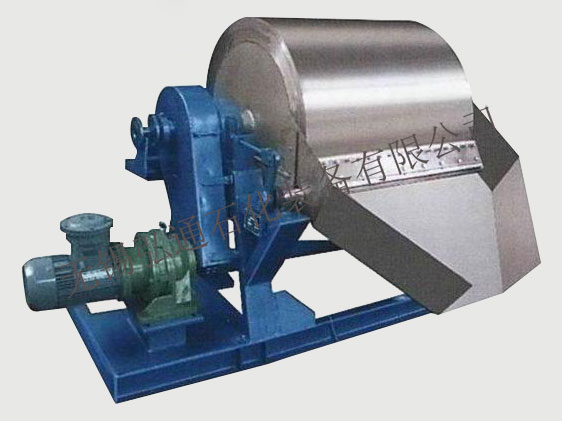

转鼓结片机是一个冷却结晶过程,料盘中熔融料与冷却的转鼓接触,在转鼓表面形成料膜,通过料膜与股壁间的换热,使料膜冷却、结晶、结晶的料膜被刮刀刮下,成为片状产品。

转鼓干燥是通过转动的转鼓,以传热的方式,将附在转鼓外壁的物料或带状物料进行加热干燥的一种连续操作的过程。 Drum flaker is a cooling crystallization process. The melt in tray will contact with cooled drum and form a layer of membrane on drum surface. The membrane cools down and crystallizes by heat exchanging between membrane and drum wall. The crystallized membrane will be scraped off to form flaked product. Drum drying is a continuous operation process to heat and dry materials or strip shaped materials attached on external wall of the drum by heat transfer method when the drum is rotating. |

|

|

设备特点 Features of the equipment 设有侧刮刀,避免转鼓侧端积料 It is set with side scraper which avoids material accumulating on side of the drum side product material 设备结构紧凑,占地面积小 Compact structure of the equipment with small floor area 半管夹套式料盘,安全可靠 Semi-pipe jacketed tray which is safe and reliable 雾化冷却,冷却效果好 |

无级变速,转鼓转速可调

Infinitely variable speed and adjustable drum speed 转鼓精度高 High precision of the drum 适应范围广,操作简便、灵活 Wide application scope with easy and flexible operation 采用多组刮刀,调节灵活 Many groups of scrapers are used which realize flexible regulating 多功能,既可结片又可干燥 Multi-functional for flaking and drying |

| 主要技术参数参考表/Reference table of main technical parameters |